Detailed process model description for the Inorganic demo

Model specification

Introduction

Intended audience

The present document is oriented to:

-

Model developers

-

Model users

-

System Integrators.

Scope

The scope of the present document is to describe the capabilities of the Inorganic demo, for the process modeling of a purification process for inorganic products.

The process is exemplificative of a class of water-phase purification processes based on multistage counter-current washings, found in the mining and electronic waste processing industries.

This demo shows off the sub-flowsheeting features of LIBPF®, which make it easy to navigate this moderately complex process (100+ streams and 70 units).

Prerequisites

-

basic knowledge of process engineering and / or of inorganic processing.

-

know about the different roles involved with the lifecycle of solutions developed using the LIBPF® enabling technology, see LIBPF® Technology Introduction

Inorganic kernel

In LIBPF® one kernel can support many process models, each as a different flowsheet type.

All the process models supported by a kernel share the same list of components and can use all LIBPF® embedded types plus the custom types registered by the kernel itself.

Type list

The Inorganic kernel registers the following models, based on the built-in LIBPF® FlowSheet type:

| Type | Description | options | Note |

|---|---|---|---|

| Inorganic | Purification process based on acid attacks and multistage, counter-current washings | default model type | |

| Attacco | Attack washing | number of stages | |

| Stadio | Single attack stage |

Additionally the following reaction types are defined, starting from the built-in ReactionYield type:

| Type | Description |

|---|---|

| ReactionSalt2 | Attack of Metal2 with Chemical1 |

| ReactionInert | Inert reaction |

| ReactionChemical4 | Inert attack with Chemical1 |

| ReactionMetal1Decomposition | Decomposition of the Metal1 water aggregate |

| ReactionMetal1 | Reacion of Metal1 with water to produce the aggregate |

| ReactionH2O2 | Elimination of hydrogen peroxide |

| ReactionChemical3 | Combination of Chemical3 with water |

Component list

The fluids to be processed are broken down in their constituents and represented as a mixture of basic components.

The components are defined using built-in LIBPF® basic types.

More precisely the Inorganic kernel defines the following component list (click on the component type to jump to the reference documentation for the component):

| Type | Name | Description |

|---|---|---|

| purecomps::water | water | standard model for water |

| purecomps::H2 | hydrogen | standard model for hydrogen |

| Chemical1 | first attack chemical | custom component |

| Chemical2 | second attack chemical | custom component |

| Chemical3 | third attack chemical | custom component |

| Chemical4 | fourth attack chemical | custom component |

| Inert | inert component | custom component |

| Metal1 | first metal | custom component |

| Metal2 | second metal | custom component |

| Salt1 | first salt | custom component |

| Salt2 | second salt | custom component |

Process descriptions and schemes

Inorganic

The objective of the purification process is to reduce impurities of “Metal2” from “Metal1” using acid attacks with four different chemicals and multistage, counter-current washings.

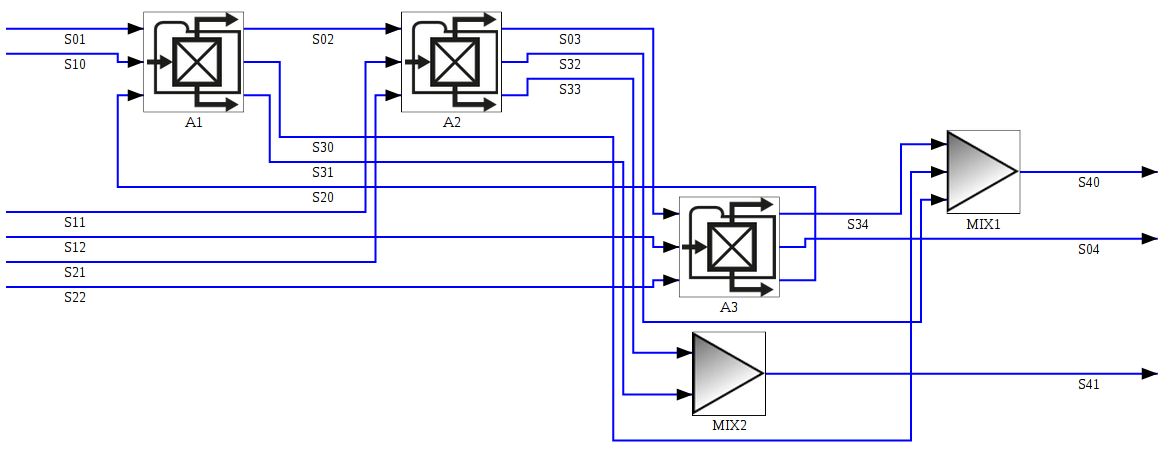

This is the full process flowsheet and makes use of the Attacco and Stadio sub-flowsheets.

The following process flow diagram should clarify the process.

There are three attack sections:

-

in the first section, the inlet solid (S01) composed predominantly of Metal1 with Metal2 and Inert impurities is treated with S10, a mixture of the Chemical1 and Chemical2 (non-reacting adjuvant) and then washed in a single stage with a recovery stream S20 of diluted filtrate (low acidity water) from counter-current washings from third attack; the main product from the first section is the washed solid outlet S02, whereas the concentrated attack filtrate S30 and the diluted washing filtrate S31 are separately discharged

-

in the second section, the washed solid outlet S02 from the first section is treated with a mixture (S11) of the Chemical4 and Chemical2 (non-reacting adjuvant) and then washed in a single stage with osmotic water S21; the main product is the washed solid outlet S03, whereas the concentrated attack filtrate S32 and the diluted washing filtrate S33 are separately discharged

-

in the third section, the washed solid outlet S03 from the second section is treated with pure Chemical1 (S12) and then washed in three counter-current stages with osmotic water S22; the main product is the washed solid outlet S04, practically free from Metal2; only the concentrated attack filtrate S34 is discharged, as the diluted washing(s) filtrate S20 is employed as fresh wash water in the first section.

The waste waters are collected separately as high-acidity waters S40 (from the concentrated filtrates S30, S32 and S34) and low-acidity waters (from the washings S31 and S33).

Stream list

The streams are defined using built-in LIBPF® basic types.

Click on the type to jump to the reference documentation for the stream.

| Type | Name | Description | From | To | options |

|---|---|---|---|---|---|

| StreamSimpleLiquidSolid | S01 | Metal1 and Inert | source out | A1 in1 | |

| StreamSimpleLiquidSolid | S02 | Solid from first attack | A1 out1 | A2 in1 | |

| StreamSimpleLiquidSolid | S03 | Solid from second attack | A2 out1 | A3 in1 | |

| StreamSimpleLiquidSolid | S04 | Solid from third attack | A3 out1 | sink in | |

| StreamSimpleLiquid | S10 | Reactants to first attack | source out | A1 in2 | |

| StreamSimpleLiquid | S11 | Reactants to second attack | source out | A2 in2 | |

| StreamSimpleLiquid | S12 | Reactants to third attack | source out | A3 in2 | |

| StreamSimpleLiquidSolid | S20 | Sour waters from counter-current washings from third attack | A3 out3 | A1 in3 | |

| StreamSimpleLiquidSolid | S21 | Osmotic water to second attack washing | source out | A2 in3 | |

| StreamSimpleLiquidSolid | S22 | Osmotic water to third attack washing | source out | A3 in3 | |

| StreamSimpleLiquidSolid | S30 | Filtrate from first attack | A1 out2 | MIX1 in | |

| StreamSimpleLiquidSolid | S31 | Sour water from first attack washing | A1 out3 | MIX2 in | |

| StreamSimpleLiquidSolid | S32 | Filtrate from second attack | A2 out2 | MIX1 in | |

| StreamSimpleLiquidSolid | S33 | Sour water from second attack washing | A2 out3 | MIX2 in | |

| StreamSimpleLiquidSolid | S34 | Filtrate from third attack | A3 out2 | MIX1 in | |

| StreamSimpleLiquidSolid | S40 | High acidity waters | MIX1 out | sink in | |

| StreamSimpleLiquidSolid | S41 | Low acidity waters | MIX2 out | sink in |

Unit list

The unit operations are defined using built-in LIBPF® basic types and the Attacco type defined by the kernel.

Click on the type to jump to the reference documentation for the unit operation.

| Type | Name | Description | options |

|---|---|---|---|

| Attacco | A1 | First attack | 3 reactions: ReactionMetal1Decomposition, ReactionSalt2 and ReactionInert |

| Attacco | A2 | Second attack | 2 reactions: ReactionMetal1, ReactionChemical4 |

| Attacco | A3 | Third attack | one reaction: ReactionInert |

| Mixer | MIX1 | Low acidity water mixer | |

| Mixer | MIX2 | High acidity water mixer |

Model options

This model has no options.

Attacco

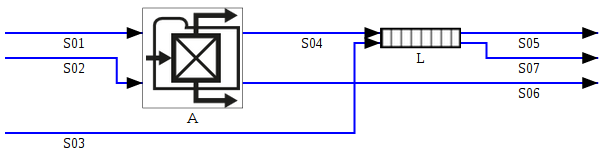

The Attacco sub-flowsheet represents an attack section and its integrated multi-stage washings, and is used in the Inorganic full flowsheet.

The following process flow diagrams should clarify the processes:

The Attacco sub-flowsheet represents an attack section and its integrated (optionally) multi-stage counter-current washing(s), and is used in the Inorganic full flowsheet.

The inlet solid (S01) and the chemicals (S02) are fed to the attack stage A.

The attack solid outlet S04 proceeds to the (optionally) multi-stage counter-current washing(s) L, where the chemicals residues are removed with the help of inlet water S03.

The main product is the washed solid outlet S05.

The concentrated attack filtrate S06 and the diluted washing(s) filtrate S07 are separately discharged.

Stream list

The streams are defined using built-in LIBPF® basic types.

Click on the type to jump to the reference documentation for the stream.

| Type | Name | Description | From | To | options |

|---|---|---|---|---|---|

| StreamSimpleLiquidSolid | S01 | Solido in ingresso | source out | A in1 | |

| StreamSimpleLiquidSolid | S02 | Reagente in ingresso | source out | A in2 | |

| StreamSimpleLiquidSolid | S03 | Lavaggio in ingresso | source out | L in2 | |

| StreamSimpleLiquidSolid | S04 | Uscita Attacco | A out1 | L in1 | |

| StreamSimpleLiquidSolid | S05 | Solido in uscita | L out1 | sink in | |

| StreamSimpleLiquidSolid | S06 | Filtrato concentrato | A out2 | sink in | |

| StreamSimpleLiquidSolid | S07 | Filtrato diluito | L out2 | sink in |

Unit list

The unit operations are defined using built-in LIBPF® basic types and the Stadio type defined by the kernel.

Click on the type to jump to the reference documentation for the unit operation.

| Type | Name | Description | options |

|---|---|---|---|

| Stadio | A | Acid attack stage | stream_type = StreamSimpleLiquidSolid |

| MultiStage | L | Washing | number of stages, 2 streams, option[1] = bottomtop, stream_type = StreamSimpleLiquidSolid, typeT (type of the model) = Stadio, typeU (type of top-bottom streams) = StreamSimpleLiquidSolid, typeV (type of bottom-top streams) = StreamSimpleLiquidSolid |

Model options

This model is parameterized by the number of wash stages; only one-stage and three-stage processed are used

Stadio

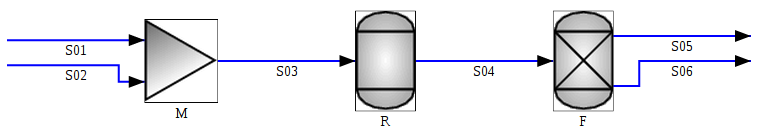

The Stadio sub-flowsheet represents a single attack or washing stage, and is used in the Attacco sub-flowsheet.

The following process flow diagram should clarify the process.

The inlet solid (S01) and the chemicals or the water (S02) are mixed in M and enter as S03 the resuspension reactor R where the (optional) reactions take place.

The reactor outlet S04 is filtered in F and separated in solid outlet S05 and filtrate S06.

Stream list

The streams are defined using built-in LIBPF® basic types.

Click on the type to jump to the reference documentation for the stream.

| Type | Name | Description | From | To | options |

|---|---|---|---|---|---|

| StreamSimpleLiquidSolid | S01 | Inlet solid | source out | M in | |

| StreamSimpleLiquidSolid | S02 | Inlet reactant | source out | M in | |

| StreamSimpleLiquidSolid | S03 | Reactor inlet | M out | R in | |

| StreamSimpleLiquidSolid | S04 | Reactor outlet | R out | F in | |

| StreamSimpleLiquidSolid | S05 | Solid outlet | F out2 | sink in | |

| StreamSimpleLiquidSolid | S06 | Filtrate | F out1 | sink in |

Unit list

The unit operations are defined using built-in LIBPF® basic types.

Click on the type to jump to the reference documentation for the unit operation.

| Type | Name | Description | options |

|---|---|---|---|

| Mixer | M | Mixer | |

| FlashDrum | R | Resuspension reactor | |

| Separator | F | Filter | streams to separate = 2 |

Model options

This model is parameterized by the stream type.